[quote=Karl;5500]Hi Dan,

would it not be worth trying one out? as the old saying goes "nothing ventured, nothing gained". It might just work out, and if it does you save a lot of addition work, cost, etc. If the worst comes to the worst you can still progress with the keyed sleeve idea.

Having a special sleeve made will only push the costs up.[/quote]

Hi Karl,

Yep I've had one of these in the C5 for the last couple of weeks using an original bearing and sleeve with no problems, but this sort of thing will need comprehensive testing. I don't plan to sell them, rather make the CAD files available to those wanting to print their own.

We still need a replacement for the sleeve, as it's not something I've seen available anywhere, which I think Chas might have cracked now anyway.

Thanks!

Dan

posted on: 22/04/2015 17:02:38

Suggestions and comments most welcome!

Suggestions and comments most welcome!

Will see how it performs on the road later when the rain has stopped

Will see how it performs on the road later when the rain has stopped

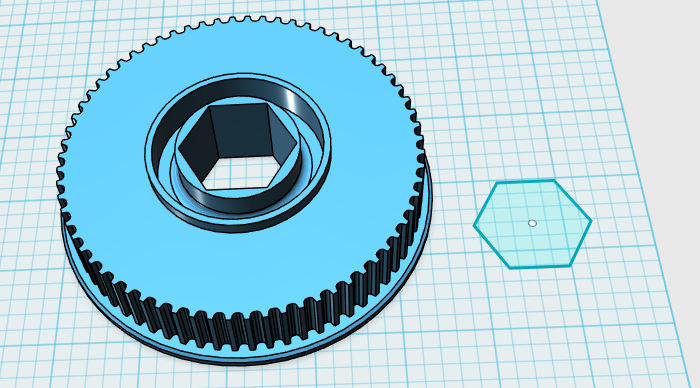

It's tight, but does fit. Just waiting for the printer to knock 1 out to test it for real

It's tight, but does fit. Just waiting for the printer to knock 1 out to test it for real

The smaller one has 60 teeth for use with

The smaller one has 60 teeth for use with